Pressure Testing: Ensuring Safety and Efficiency with Advanced Technologies

Introduction

Pressure testing is an important process in many industries because it ensures the safety, dependability, and efficiency of components and systems. This article will go over the different types of pressure testing, such as burst pressure testing, leak testing, pressure cycle testing, and autofrettage. We’ll also discuss the advantages of pressure testing and give an overview of our company, Poppe + Potthoff Maschinenbau, which specializes in advanced pressure test rigs. Let’s get started and learn about pressure testing!

What is Pressure Testing?

Pressure testing is a method of determining the fatigue strength and integrity of pressure vessels such as hoses, tubes, cooling circuits, accumulators, and other equipment that is subjected to internal pressure. It is critical to ensure that these components can withstand the predetermined pressures without rupturing, leaking, or failing in any other way. Pressure testing is important in many industries because it helps to maintain safety standards, improve product performance, and reduce the risk of costly failures that result in vehicle callbacks, for example.

Types of Pressure Testing

3.1 Burst Pressure Testing

Burst pressure testing is a procedure that involves subjecting a component to increasing pressure until it fails – or bursts. The purpose of this destructive test is to determine the maximum pressure that a component can withstand before rupturing. It assists manufacturers in designing components that can safely withstand the pressure levels encountered during operation. It provides useful information about the maximum pressure that a component can withstand, even if the operating pressure is much lower. Oil, water, glycol, and a variety of gases can all be used in burst tests.

3.2 Leak Testing

Leak testing is the process of inspecting components for leaks while under pressure. This test ensures that components do not leak and retain their integrity when subjected to internal pressure. Leak testing is critical in industries where leaks can pose a safety risk or impair performance. Underwater (bubble test) leak tests are commonly used to pinpoint exactly where the device under test (DUT) is compromised. Water, oil, glycol, and a variety of gases are common leak-testing fluids.

3.3 Pressure Cycle Testing

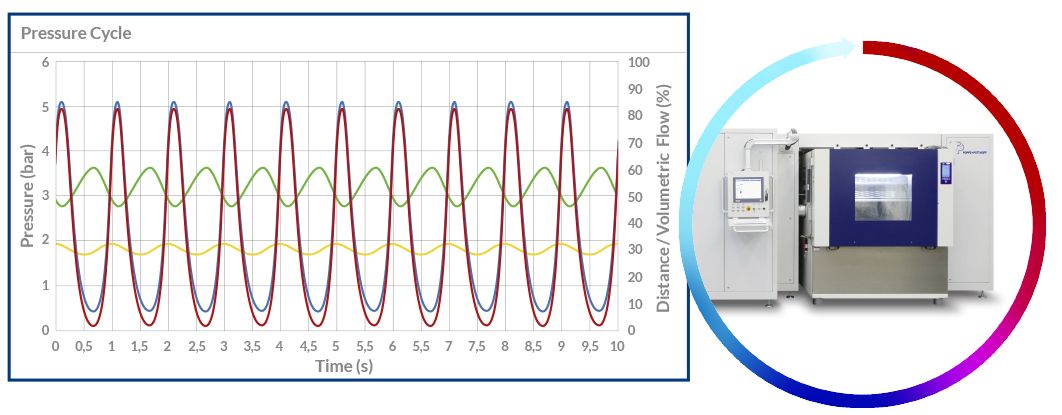

The process of subjecting components to changing pressure cycles of pressurization and depressurization is known as cyclic pressure testing. This test determines the fatigue resistance of the component as well as its ability to withstand cyclic pressure loads during its service life. Water, glycol emulsion, coolant, or oil are common test media. Furthermore, it is common to incorporate media heating and cooling capacities, as well as expose the DUT to changing temperatures via a climate or temperature chamber. The test is typically performed in the form of a sinusoidal or trapezoid curve, also known as a wave or square pressure curve.

3.4 Autofrettage

The process of subjecting components to changing pressure cycles of pressurization and depressurization is known as cyclic pressure testing. This test determines the fatigue resistance of the component as well as its ability to withstand cyclic pressure loads during its service life. Water, glycol emulsion, coolant, or oil are common test media. Furthermore, it is common to incorporate media heating and cooling capacities, as well as expose the DUT to changing temperatures via a climate or temperature chamber. The test is typically performed in the form of a sinusoidal or trapezoid curve, also known as a wave or square pressure curve.

Benefits of Pressure Testing

Pressure testing provides numerous benefits, including:

- Ensuring the safety and reliability of components and systems.

- Detecting defects and potential failure points early in the manufacturing process.

- Reducing the risk of costly failures and downtime.

- Enhancing product performance by optimizing design and material selection.

- Complying with industry standards and regulations.

5. Poppe + Potthoff Maschinenbau: An Overview

Poppe + Potthoff Maschinenbau is a pioneer in the development of advanced pressure testing solutions. We specialize in custom pressure testing systems for a variety of industries, including automotive, aerospace, oil and gas, and medical technology components. Our cutting-edge systems include a variety of advanced features that enable precise, dependable, and efficient pressure testing.

5.1 Poppe + Potthoff Maschinenbau Advanced Features

5.1.1 Programmable Pressure Curves

Pressure testing systems from Poppe + Potthoff Maschinenbau feature programmable pressure curves, allowing users to simulate real-world operating conditions. This feature allows components to be tested under a variety of pressure profiles, including sinusoidal, trapezoidal for cyclic pressure applications, and custom-designed curves, to ensure optimal performance in real-world applications.

5.1.2 Safety

Poppe + Potthoff Maschinenbau places a high value on safety. Our pressure testing systems are built with numerous safety features, such as pressure relief valves, emergency stop buttons, safety interlocks, burst flaps, and, most importantly, secure and robust test chambers, to ensure the safety of the equipment and the protection of the operators.

5.1.3 Integration of Temperature and Climate Chambers

Pressure testing systems from Poppe + Potthoff Maschinenbau can be integrated with temperature and climate chambers, allowing components to be tested in a variety of temperature and humidity conditions. This feature enables manufacturers to assess the performance and durability of their products in real-world environments. We are open to incorporating test chambers from a variety of vendors. A test rig with a CTS chamber is shown below.

5.1.4 Heated and Cooled Test Media

To simulate actual operating conditions, the company’s pressure testing systems can use heated and cooled test media such as water, oil, or glycol. This feature enables users to evaluate component performance under various temperature conditions, ensuring optimal performance in their intended application. The temperature can be adjusted using the operating system. We can integrate any media heating unit and have worked with companies such as Autotherm and Lauda.

5.1.5 Custom Pressure Rig Design

Poppe + Potthoff Maschinenbau specializes in creating custom pressure testing rigs that are tailored to specific customer needs. This customization ensures that the testing equipment accurately addresses the unique challenges and operating conditions of each industry, as well as the component peculiarities of the customers, resulting in reliable and accurate test results.

Conclusion

Pressure testing is an important process that ensures the safety, dependability, and efficiency of components and systems in a variety of industries. Manufacturers can improve the quality and performance of their components by understanding the various types of pressure testing, such as burst pressure testing, leak testing, pressure cycle testing, and autofrettage. Poppe + Potthoff Maschinenbau’s advanced pressure testing solutions provide precise and reliable testing results to meet the demands of today’s industries.

FAQs

Q1: What is the purpose of pressure testing?

A1: Pressure testing is used to determine the strength and integrity of pressure vessels, pipelines, and other equipment subjected to internal or external pressure. It helps ensure that these components can withstand the required pressure without rupturing, leaking, or experiencing other failures.

Q2: What industries commonly use pressure testing?

A2: Pressure testing is widely used in various industries, including oil and gas, automotive, aerospace, pharmaceutical, and food and beverage.

Q3: What is the difference between burst pressure testing and leak testing?

A3: Burst pressure testing determines the maximum pressure a component can withstand before it ruptures, while leak testing examines components for leaks under pressure.

Q4: How does autofrettage improve component performance?

A4: Autofrettage subjects a component to high pressure, causing plastic deformation and resulting in residual compressive stresses. These stresses improve the component’s fatigue life and pressure resistance.

Q5: What sets Poppe + Potthoff Maschinenbau apart from other pressure testing equipment manufacturers?

A5: Poppe + Potthoff Maschinenbau specializes in custom-designed pressure testing systems with advanced features, such as programmable pressure curves, integration of temperature and climate chambers, and the use of heated and cooled test media. These features enable precise, reliable, and efficient pressure testing across various industries and applications.

Q6: What are sinusoidal and trapezoidal pressure curves?

A6: Sinusoidal and trapezoidal pressure curves are specific types of pressure profiles used in pressure testing. A sinusoidal curve represents a smooth, continuous wave-like pattern, while a trapezoidal curve features linear increases and decreases in pressure with flat plateaus at the peak and trough. These curves help simulate real-world operating conditions during pressure testing, ensuring the tested components perform optimally in their intended applications.

Q7: How does the integration of temperature and climate chambers benefit pressure testing?

A7: Integrating temperature and climate chambers with pressure testing systems allowing manufacturers to evaluate the performance and durability of their components under various temperature and humidity conditions. This capability ensures that components will perform optimally under real-world environmental conditions, enhancing product reliability and performance.