Pressure Test Rigs For

Oil and Gas Components

Typical oil and gas components and DUTs tested on a Poppe + Potthoff pressure test rig are drill pipes, tubes, and valves. These components are exposed to pressure and changing temperature conditions which require testing to ensure quality and safety.

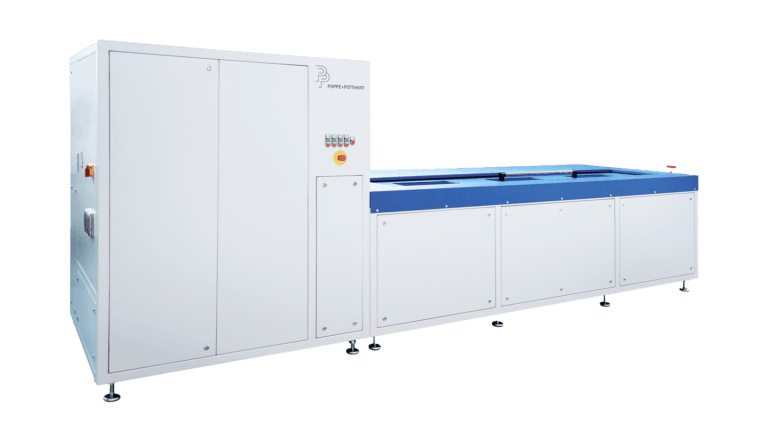

Hose Test Bench with Laser Measurement

When hoses are subjected to pressure, they often change from their original form and dimension. The test stand has an integrated automatic laser and length measurement system and can measure torsion easily. In addition, a quick connector system enables the hoses to be replaced rapidly.

Burst and Pressure Cycle Test Stand

A state-of-the-art dual chamber test rig for simultaneous burst and pressure pulsation testing. The rig enables testing flexibility in your lab. A media heating and cooling unit can be installed to cover an even wider range of test requirements.

Double Chamber Test Rig for Burst and Pressure Cycle Tests of Coolant Hoses

Our flagship double-chamber test bench can test up to 10 DUTs (e.g. coolant hoses) simultaneously. In addition, we enable ambient and fluid temperatures of -60°C to 180°C. Further, our test rig is equipped with separate 3x media circuits to enable testing with oil, water and water glycol emulsion for dynamic pressure cycle and burst testing up to 800 bar.

Pressure Cycle Test Bench up to 6000 bar

Various components, such as diesel injection lines, pipes, and sensors are exposed to very high pulsating pressures. Consequentially, to understand the longevity of the material and component quality the service life is tested during long-term pressure cycle tests.

Standard Pressure Cycle Test Rig 500 / 1000 / 2000 bar

Our standard pressure cycle test bench serves as the basis for many of our systems. Thus, it can be upgraded with a wide variety of configurations such as media heating and cooling, high or low-pressure ranges and much more.

Pressure Pulsation Test Rig up to 600 bar

Our flagship pressure cycle test bench is a powerful and versatile pressure test bench that exposes pressure vessels to changing pressure loads. For example, cooling circuits, sensors, hoses and many others components are put to a lifetime test by applying pressure cycles. Further, a climate chamber and media heating and cooling unit enable real-life conditions. In addition, a controlled media flow can be generated up to 60 l/min.

Contact Us

Our experienced technical sales team will help you with the implementation of your project and will find a solution tailored to your specifications and your requirements. We are represented internationally and can support you and your company worldwide. Our team has completed hundreds of projects many of which involved supporting test facilities with identical equipment. P+P Maschinenbau is your internationally trusted partner.