Pressure cycle test benches up to 6,000 bar. The pressure cycle test simulates the service life of a component using a sine (wave) or trapezoidal (square) waveform. Our pressure test benches are suitable for testing metal and plastic components through to aluminium and special materials.

Pressure Cycle Tests With

Media- & ambient temperature control

Pressure Cycle Testing is also known as pressure impulse testing, pressure pulsation testing, or sinusoidal pressure testing. Consequentially it simulates the design life of a pressure vessel by exposing the DUT (device under test) to various pressure load changes.

Pressure pulsation testing finds use in many industries and ranges from low-pressure tests at 6 bar e.g. for cooling systems for electronic vehicles, but also up to 6000 bar for common rails systems. Furthermore, applications are wide-ranging and our state-of-the-art test rigs support companies in R&D and quality control and validation. Tests are frequently run with coolant, glycol, ethylene, oil, water, and more.

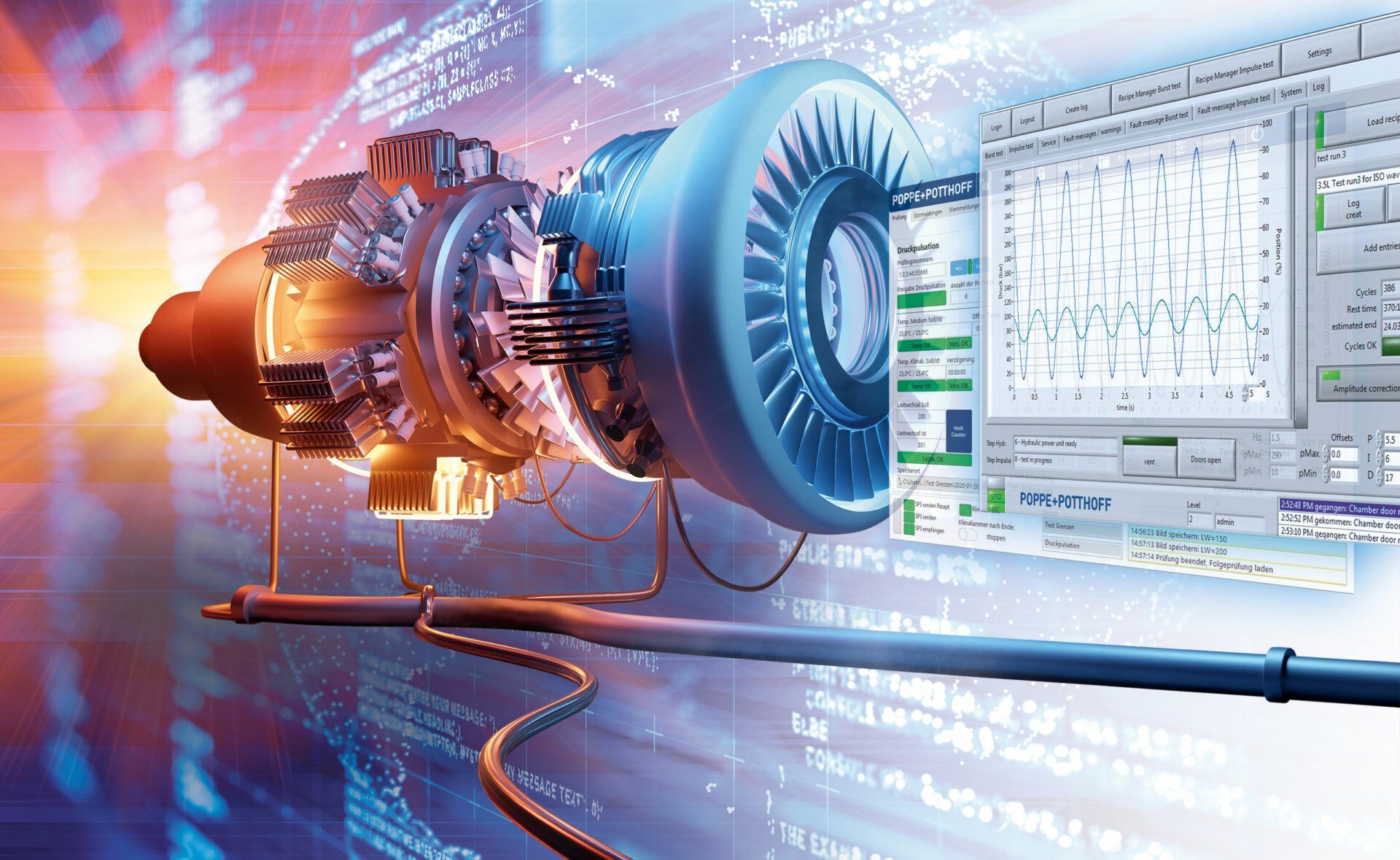

The Poppe + Potthoff pressure cycle rigs test the operating and fatigue strength of components. Furthermore, the endurance pressure test exposes potential weaknesses of components with respect to design and material. The pressure curve is flexible and the test P+P rigs can create pressure as a sine curve (wave) or a trapezoid (square) curve. For special applications, the test rigs can also run a needle pulse, also known as a water hammer test. In addition, the pressure test rigs can be run with a climate chamber to simulate ambient temperature, and also a fluid heating and cooling unit could be added.

Custom design, integration of climate chambers, and media heating and cooling

In order to simulate real-life temperature conditions, we can easily integrate a climate chamber and fluid heating and cooling unit. Further, we work closely with you to understand your test requirements and offer state-of-the-art, custom testing solutions. We work together with climate chamber manufacturers around the globe and can integrate a climate chamber for ambient temperature simulation and humidity control.

Standard Pressure Cycle Test Bench 1000 / 2000 bar

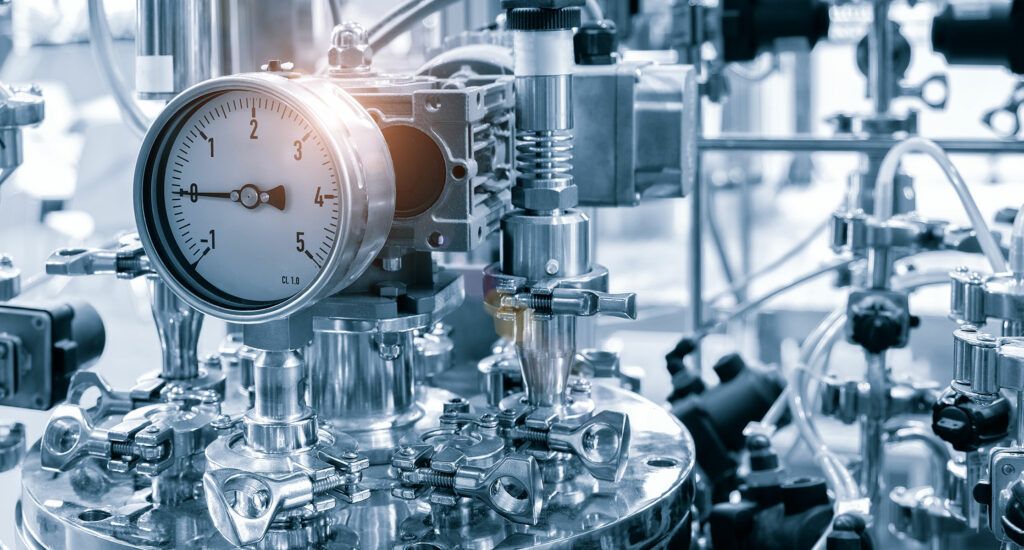

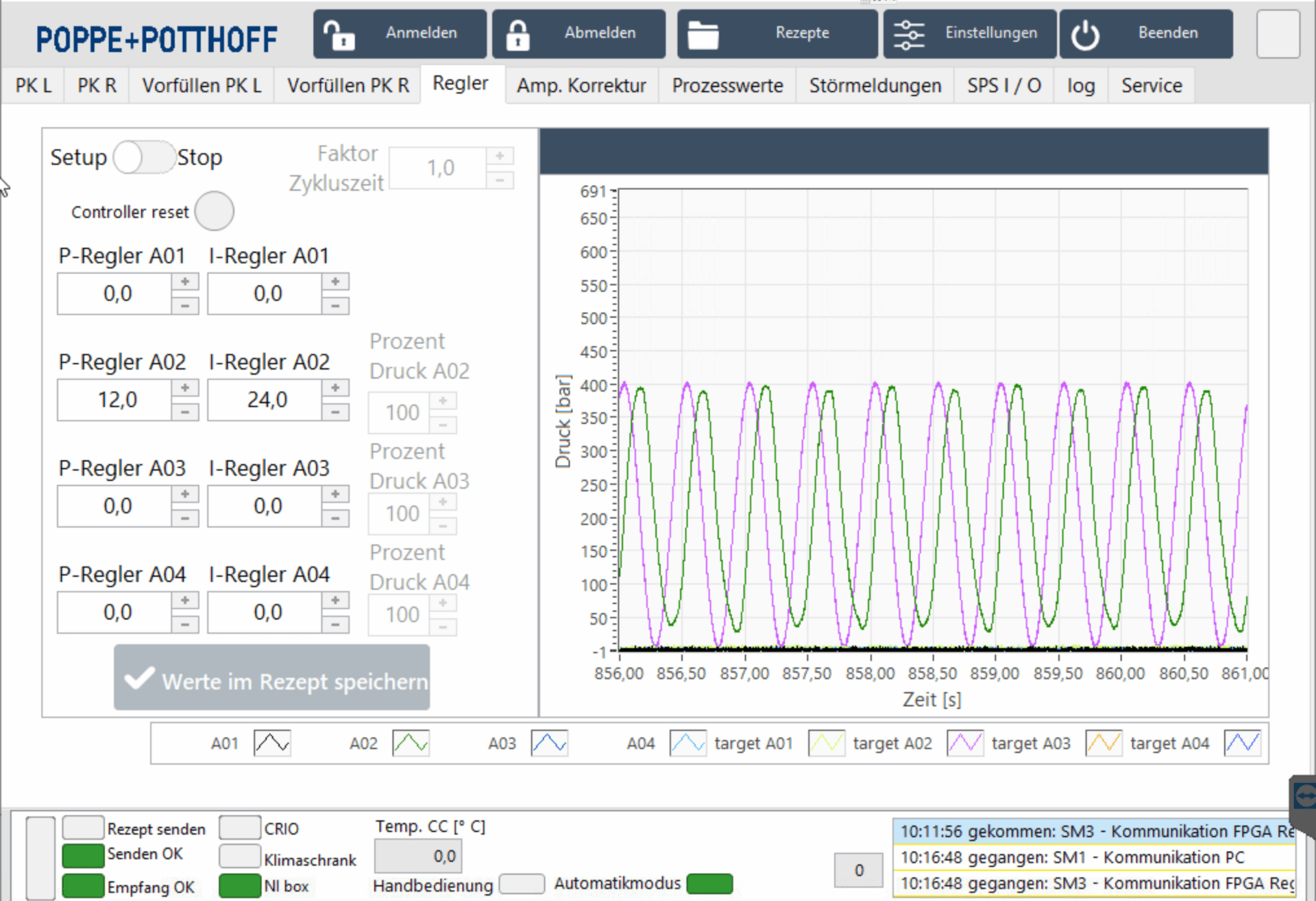

The standard impulse test stand is operated with a hydraulic pressure of 330 bar. The pressure is generated through a hydraulic power unit and drives the pressure booster via a regulation valve. The pressure booster has a constant pressure ratio and produces high pressure through linear movements. The system is equipped with high-dynamic servo-regulator valves, which guarantee precise repeatability even at very high test frequencies.

Performance Data

High-Pressure Impulse Test Rig up to 6000 bar

The pressure pulsation test reveals potential weaknesses of components in terms of component design and material composition. Exposing components to thousands or even millions of pressure load changes gives insight into the component’s structure and weak spots. Typical components that require testing at such high pressures are common rails or injector nozzles for example. The pulse pressure is generated by a pressure intensifier with a hydraulic drive. A hydraulic unit generates a constant hydraulic pressure of 350 bar and this pressure drives the pressure intensifier via a control valve. The pressure intensifier has a constant pressure ratio and generates high pressure through its linear movements. A highly dynamic servo control valve is used as the control valve, which enables very high test frequencies with precise repeatability. The course of the test pressure is measured with a pressure transducer and stored. These data sets allow the quality of the test to be assessed later. The pressure control of the system also works via this pressure sensor. Hydraulic oil is used as the test medium. An optimally tuned cooling system keeps the temperature at the pressure intensifier and in the hydraulics in balance. Cooling is a very effective water cooling.

Performance Data

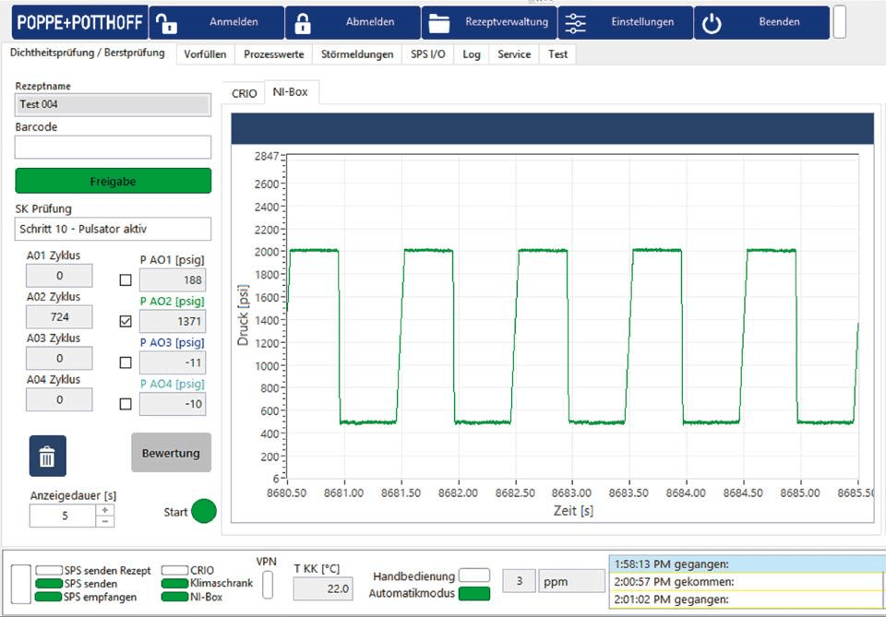

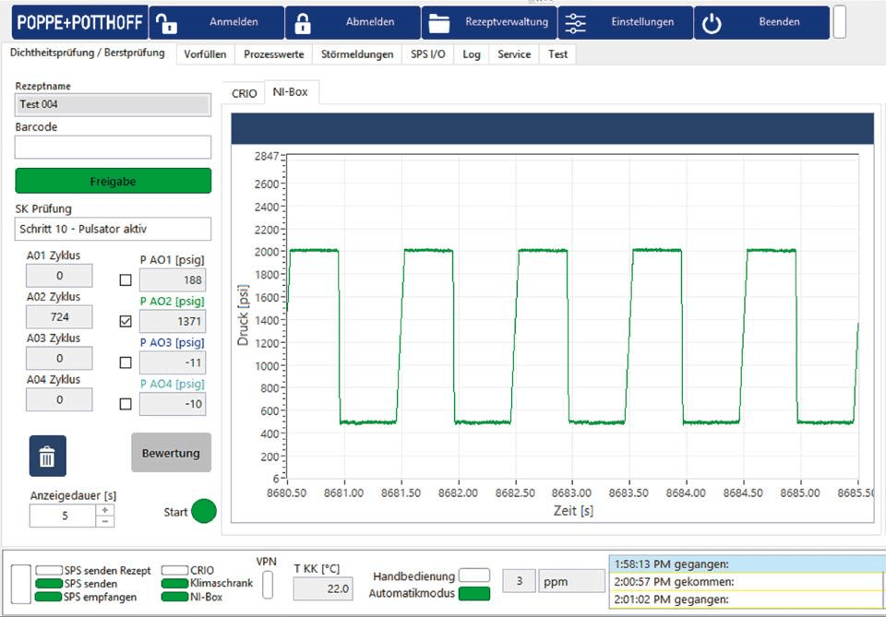

Pressure Cycle-, Burst- and Leak Testing

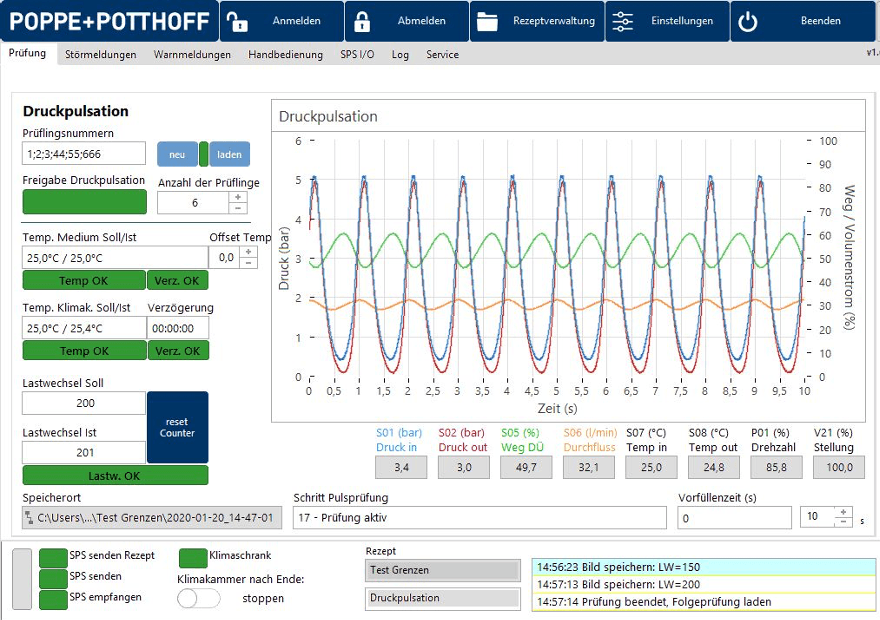

The test rig has two chambers in which up to ten DUTs can be tested at an ambient temperature of -60°C up to 180°C simultaneously. 3 separate fluid circuits allow Glycol (coolant), oil, and water for example to be used as test fluids in one test bench and therefore offer a versatile test setup for any test lab.

The climate chamber acts as the rig’s test space and enables tests at large temperature ranges to simulate real-life situations, such as tests on the racetracks on Nürburgring or Silverstone, in the Siberian tundra, or in the deserts of Africa.

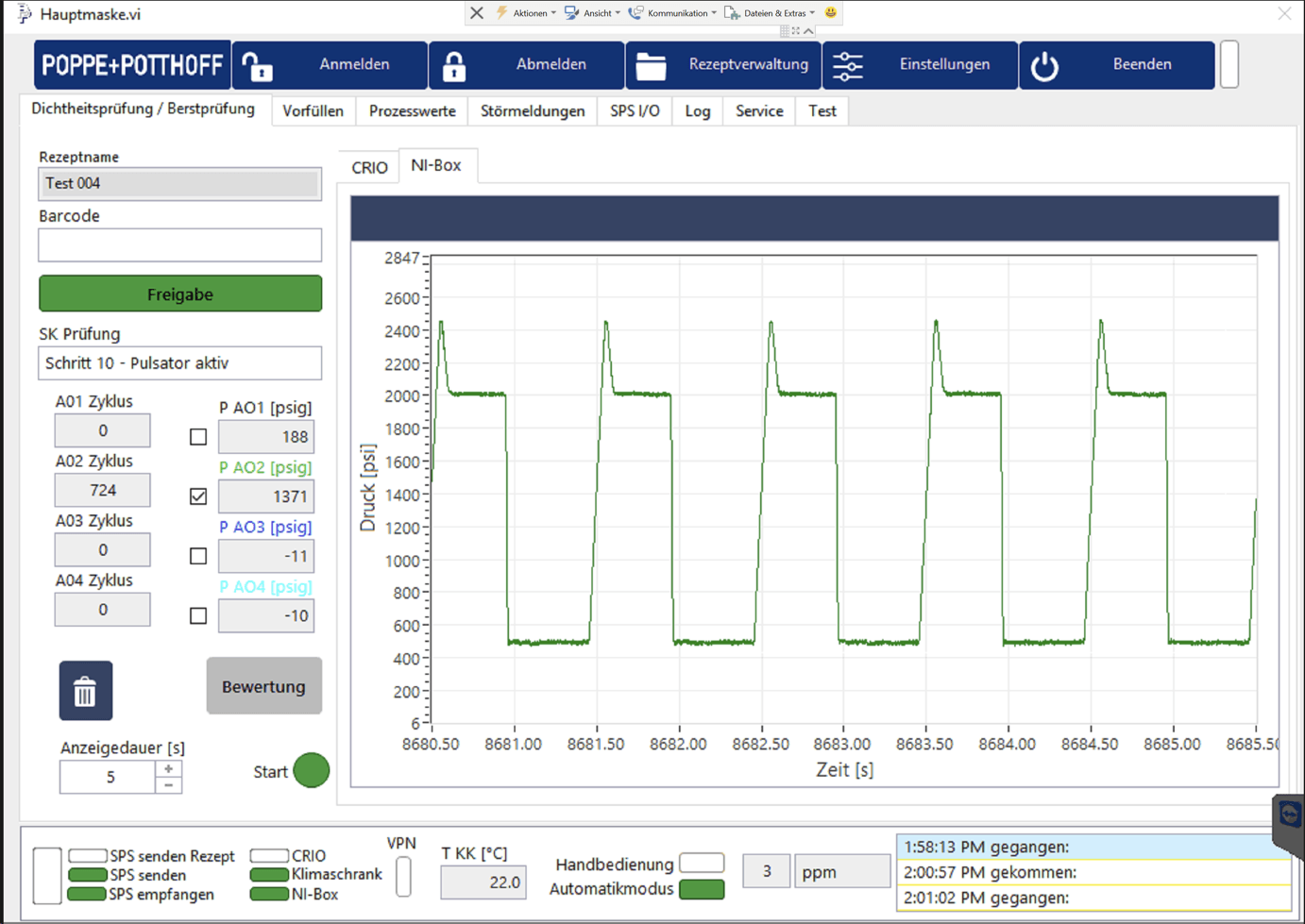

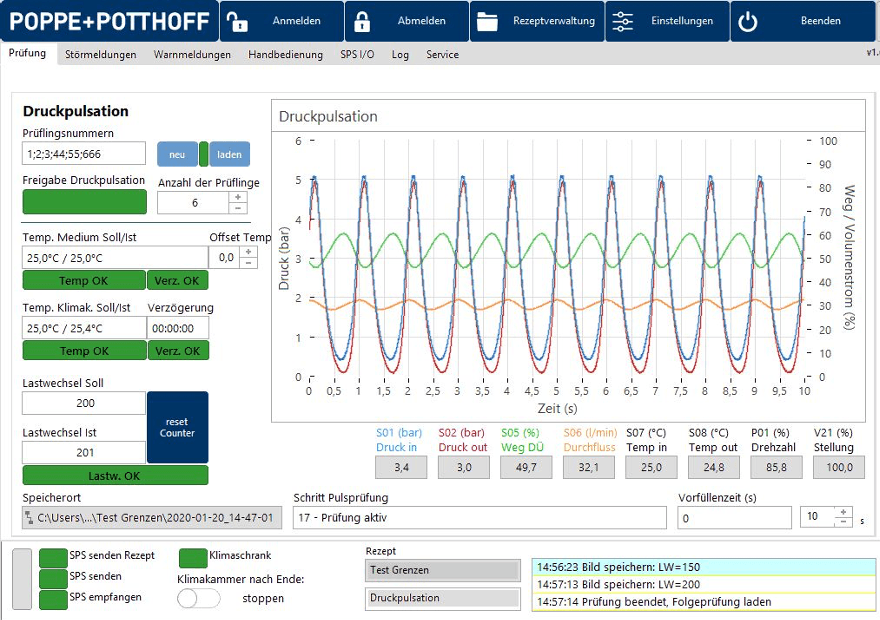

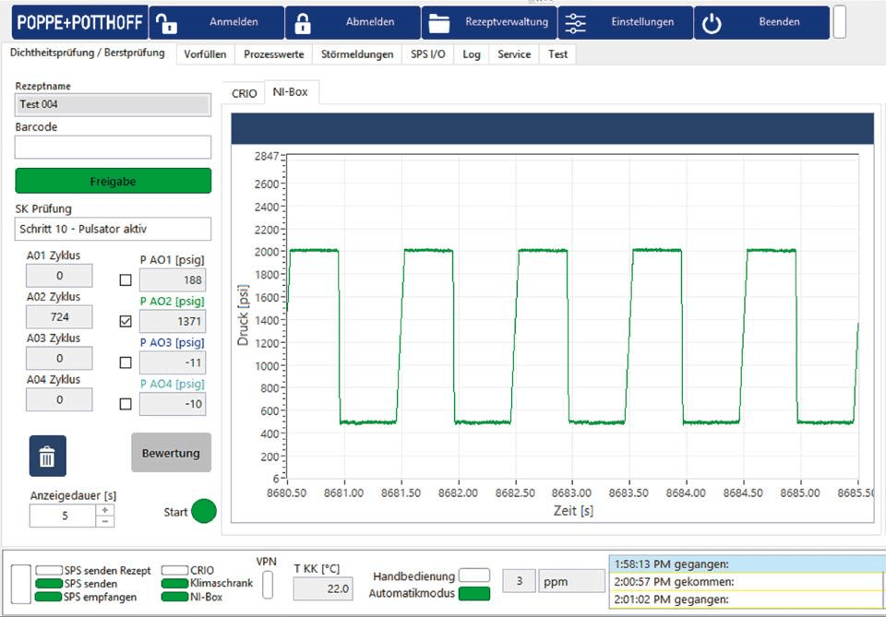

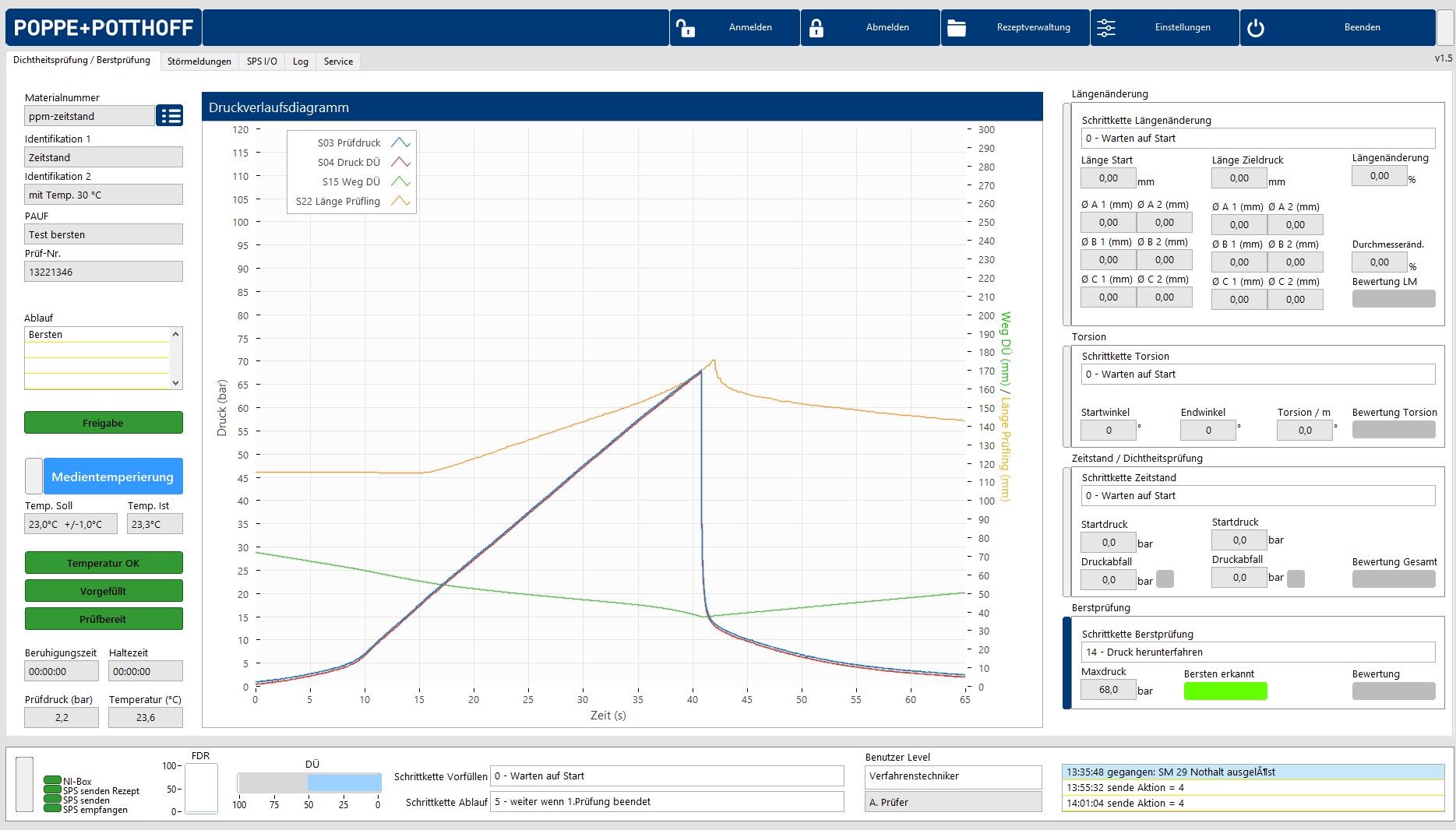

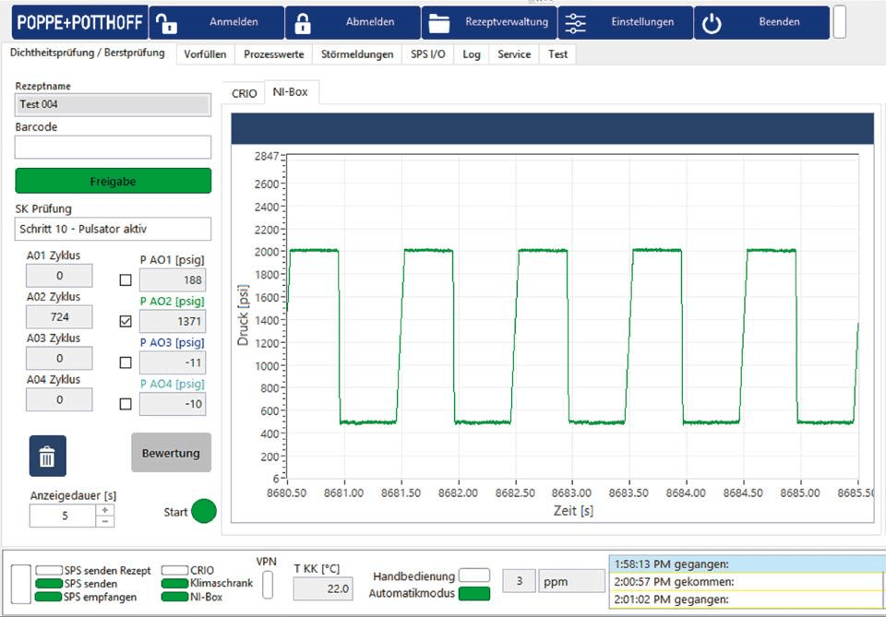

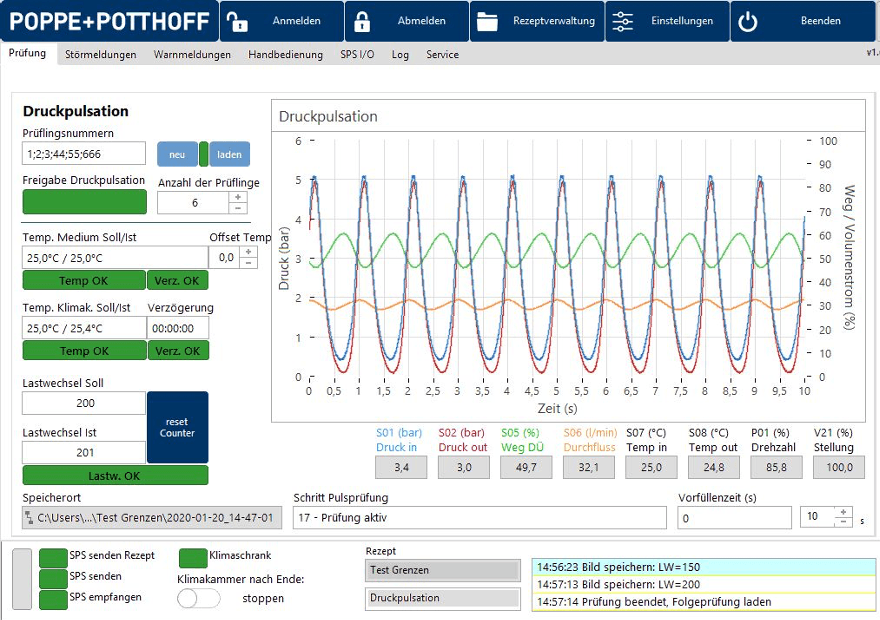

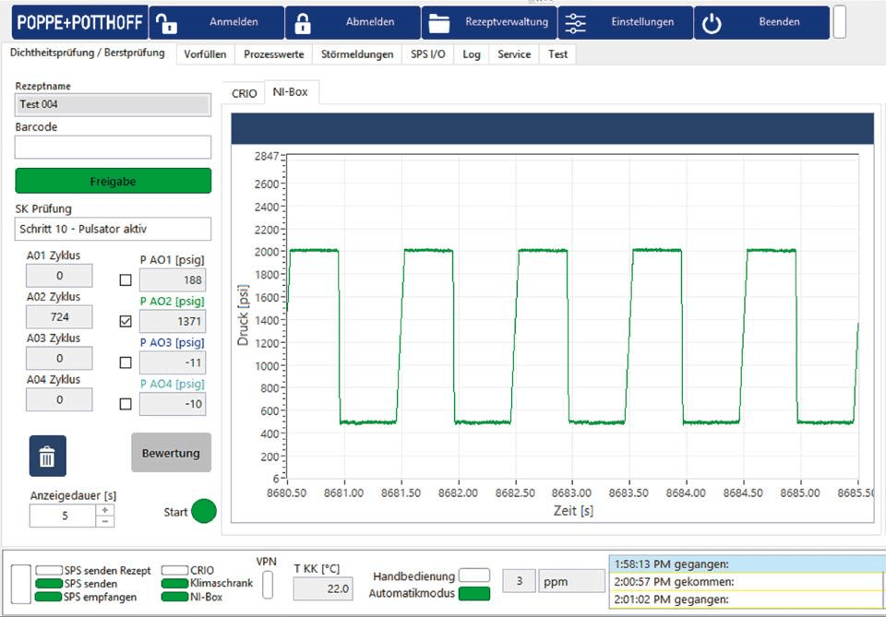

Various servo-hydraulic pressure intensifiers are tailored to each type of test, allowing very accurate control of the pressure curve. Pressure pulsation tests can be performed with a frequency of 0 – 10 Hz (most common is 0.5 – 2.5 Hz) with a trapezoid (square) curve at pressure ranges such as 4 – 25 bar for e.g. and 0 – 160 bar. The sine (wave) curve has a frequency of 0 – 10 Hz and pressures of 0 – 6 bar e.g. The maximum burst pressure is 500 bar. Data acquisition and visualization are performed using National Instruments’ LabVIEW. All test sequences and data are automatically stored on the control unit and can be exported to the company network for analysis.

Performance Data

Pressure Cycle-, Burst- and Leak Testing

The test rig has two chambers in which up to ten DUTs can be tested at an ambient temperature of -60°C up to 180°C simultaneously. 3 separate fluid circuits allow Glycol (coolant), oil, and water for example to be used as test fluids in one test bench and therefore offer a versatile test setup for any test lab.

The climate chamber acts as the rig’s test space and enables tests at large temperature ranges to simulate real-life situations, such as tests on the racetracks on Nürburgring or Silverstone, in the Siberian tundra, or in the deserts of Africa.

Various servo-hydraulic pressure intensifiers are tailored to each type of test, allowing very accurate control of the pressure curve. Pressure pulsation tests can be performed with a frequency of 0 – 10 Hz (most common is 0.5 – 2.5 Hz) with a trapezoid (square) curve at pressure ranges such as 4 – 25 bar for e.g. and 0 – 160 bar. The sine (wave) curve has a frequency of 0 – 10 Hz and pressures of 0 – 6 bar e.g. The maximum burst pressure is 500 bar. Data acquisition and visualization are performed using National Instruments’ LabVIEW. All test sequences and data are automatically stored on the control unit and can be exported to the company network for analysis.

Performance Data

R&D Pressure Pulsation Test Stand for H2 Components up to 2000 bar

P+P test stands are used in research & development and to constantly benchmark the manufacturing process and H2 component quality. To guarantee the safety of media-carrying components during their entire service life, components must undergo endurance tests under extreme load and temperature changes. P+P offers and uses flexible solutions while simulating diverse conditions and environments. Our test systems allow for leak tests with a range of more than 1050 bars, depending on the specification.

The test stand can be expanded with several expansion stages. Depending on the option selected, pressure cycle tests up to 2,000 bar and 10 Hz can be generated in addition to the gas test. Pressure ramps of up to 3,000 bar can be generated with the test circuit for hydrostatic and burst pressure tests.

The system consists of two modules. The tests can be carried out in a climate chamber, in which the components can be exposed to media and outside temperatures from -40 °F (-40 °C) to +320 °F (+160 °C). The individual printing units are precisely tailored to the properties and components of the customer in order to generate ideal test conditions. A common setup in the industry and for this specific test stand is one intensifier for 1000 psi (70 bar), two for up to 4000 psi (275 bar) and one for up to 6000 psi (414 bar). A typical test medium is water, glycol, aerospace oil, gas, and other oils.

Performance Data

Testing Components in a Climate Chamber:

e.g. Aerospace Components

The PPM 432 pulse test stand offers a powerful system for testing cooling components, hydraulic components, fluid systems, and various other pressure vessels for the aerospace industry.

For e.g. electronic units such as ECUs on board produce heat which has to be dissipated to ensure that the systems function reliably during flight. The pressure pulsation test stand simulates a controlled pressure change at various pressure ranges and temperature conditions. The system consists of two modules. The supply unit houses the pressure intensifiers, cooling and heating units, and the control system. The actual testing takes place in a climate chamber in which the DUTs are tested at a media temperature of -40°F(-40°C) to +320°F (+160°C) and changing environmental conditions from -58°F (-50°C) to +320°F (+160°C). The pressure intensifiers can be designed to the customers’ requirements and components’ idiosyncrasies. A Common setup is a pressure intensifier for up to 1000 psi (70 bar), two for up to 4000 psi (275 bar) and one for up to 6000 psi (414 bar), while Aerospace oil is used as the test medium.

Performance Data

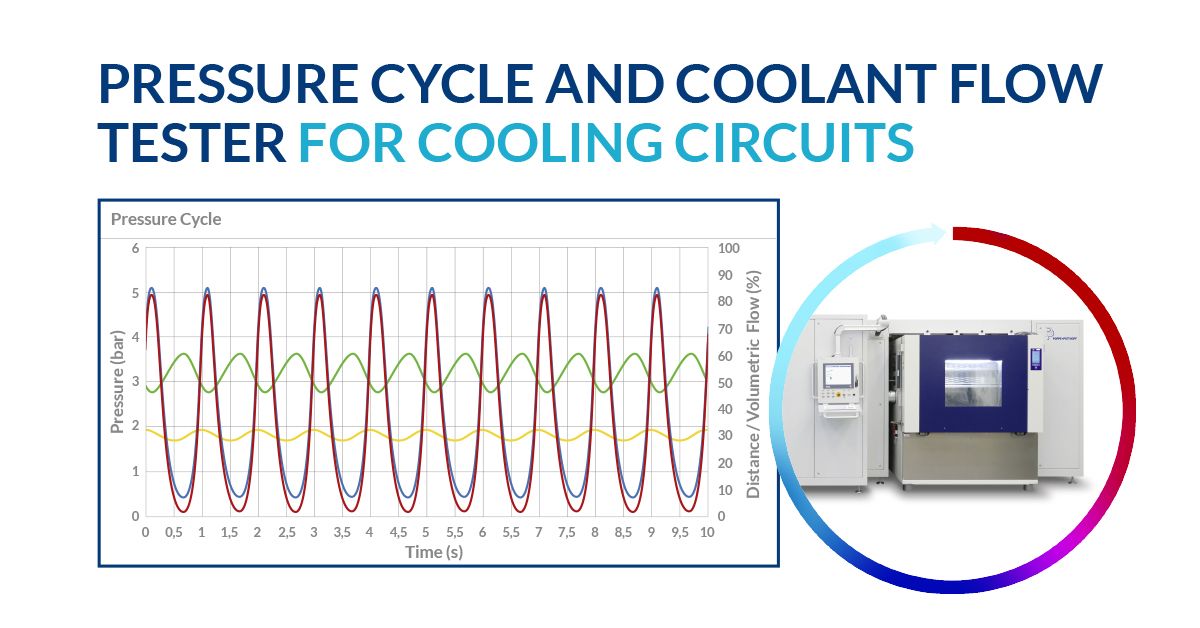

Pressure Alteration Testing Cooling Circuits

with Under- and Overload Pressure (M07)

A state-of-the-art pressure pulsation test stands with media flow control and pressures up to 12 bar. The pressure pulsation rig is a flexible system and can be adapted to customers’ testing requirements. It covers tests for industry standards such as VW8000 or BMW Group M07 with under and overload pressure, which is currently a highly requested test for electronic vehicle components. A pressure test rig is an independent unit. It contains a media temperature control unit and an integration into a climate chamber. The pressure rig is powered by up to 12 bar by a hydraulic pressure intensifier. It has the capability to perform a vacuum test with a pressure change from negative pressure to positive pressure.

Frequently pressure cycle tested DUTs are electronic control units (ECUs) and their cooling circuits and cooling plates, battery housings, AD/DC, DC/DC converters, high voltage cooling heaters (HVCH), heat exchangers, liquid-cooled power converters, and many more.

Performance Data

Pressure Testing Cold Plates of CPUs and GPUs

This cutting-edge test rig is engineered to perform comprehensive burst and pressure pulsation testing on liquid-cooled cold plates utilized in server infrastructures, drawing on methodologies refined within the automotive sector as test standards haven’t been defined yet. Our equipment is crafted to assess and confirm the durability of components and the integrity of seals amidst the dynamic pressures found in cooling circuits. Featuring a hydraulic pressure intensifier, our rigs offer unparalleled precision, achieving reliable and repeatable results across a spectrum of testing scenarios.

With the capability to administer burst pressure tests up to 35 bar (500 psi) and engage in pressure cycle testing at pressures up to 12 bar (175 psi) with the test media PG25, our systems can simulate operational conditions at frequencies reaching 2 Hz. This rigorous testing protocol is indispensable for ascertaining the dependability of cooling solutions integral to the performance of CPUs, GPUs, and related technological apparatus.

By incorporating a hydraulic pressure intensifier, it not only enhances the accuracy of pressure application but also ensures the consistency of test conditions, thereby guaranteeing the reliability of every cold plate tested. This attention to detail in simulating real-world conditions makes our testing solutions invaluable for manufacturers seeking to ensure the highest standards of product reliability in their cooling systems.

Performance Data (exemplary)

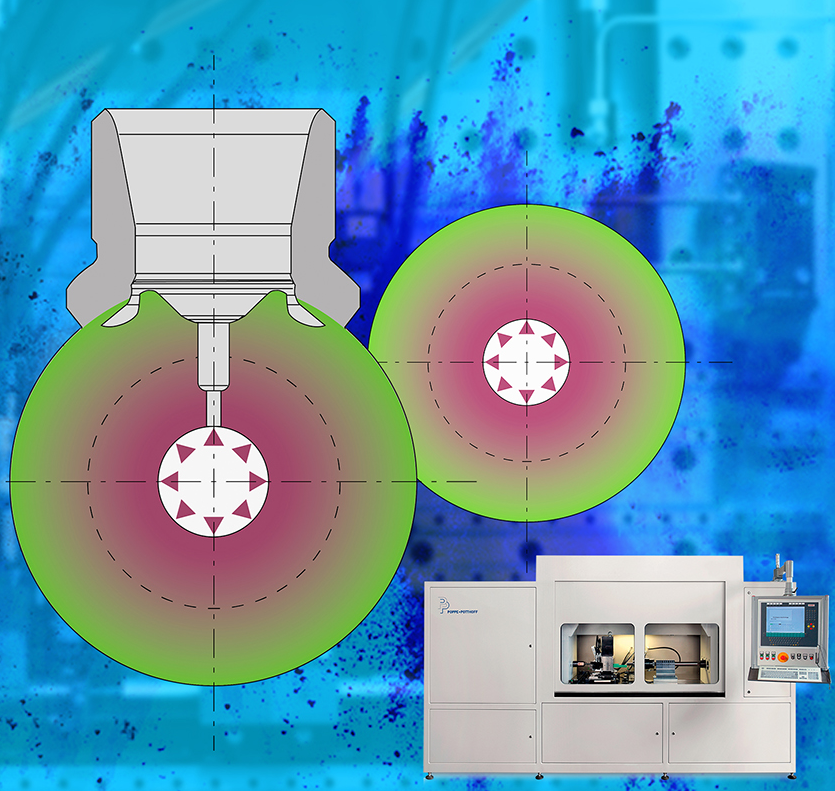

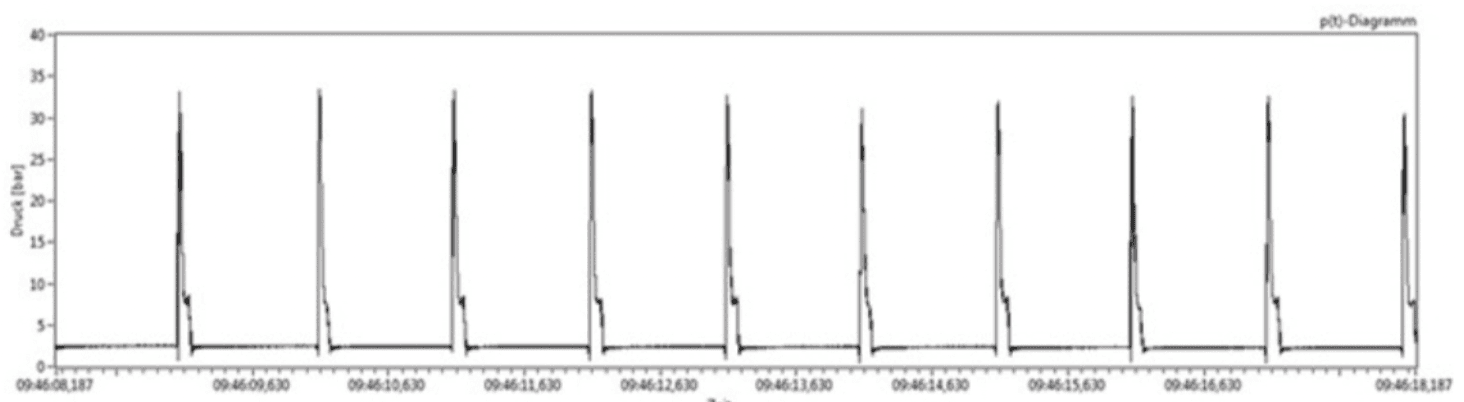

Water Hammer Test

The pressure test system has a servo-controlled hydraulic intensifier to generate pressure pulsation. This servo unit is a linear, highly dynamic feed axis. With this axis, one impulse mass is accelerated and the impulse mass hits a pressure piston. The pressure piston generates the pressure surge in the DUT. The acceleration and impact speed of the constant impulse mass is controlled by a dynamic digital controller. The level of the pressure shock is measured and the impact speed of the impulse mass is controlled via a control system. The pressure test rig can be expanded to enable burst tests.

Performance Data

Test-as-a-Service

We offer several pressure tests in various pressure ranges as a test service. Whether for research and development or serial production, please contact us with your testing requirements for a non-binding offer.

PRESSURE TEST BENCHES AND APPLICATIONS

PRECISE, REPEATABLE AND RELIABLE

As a specialist in pressure testing technology and state-of-the-art test rigs, Poppe + Potthoff Maschinenbau supports the development and production of particularly resilient components made of various materials – especially for automotive, shipbuilding and mechanical engineering as well as fluid and the medical industry. We offer individually designed test benches such as burst pressure test rigs, pressure cycle test benches, leak test systems, functional test rigs and autofrettage systems.

Contact Us

Our experienced technical sales team will help you with the implementation of your project and will find a solution tailored to your specifications and your requirements. We are represented internationally and can support you and your company worldwide. Our team has completed hundreds of projects many of which involved supporting test facilities with identical equipment. P+P Maschinenbau is your internationally trusted partner.

Know-how, excellent knowledge of the market, affinity with our products and close cooperation with you, our customers, are the guarantors of our success.